Ordering

Ramsys POS Ordering

Operations/Order Stock

The Ramsys POS ordering screen streamlines the stock ordering process for managers by allowing quick and efficient order creation.

The system automatically generates purchase orders in Ramsys Central and once approved emails them directly to suppliers, reducing manual workload and ensuring timely restocking. With intuitive controls and real-time stock data, managers can make informed purchasing decisions, keeping inventory levels optimised and operations running smoothly.

Note: this function must be enabled in your system setup.

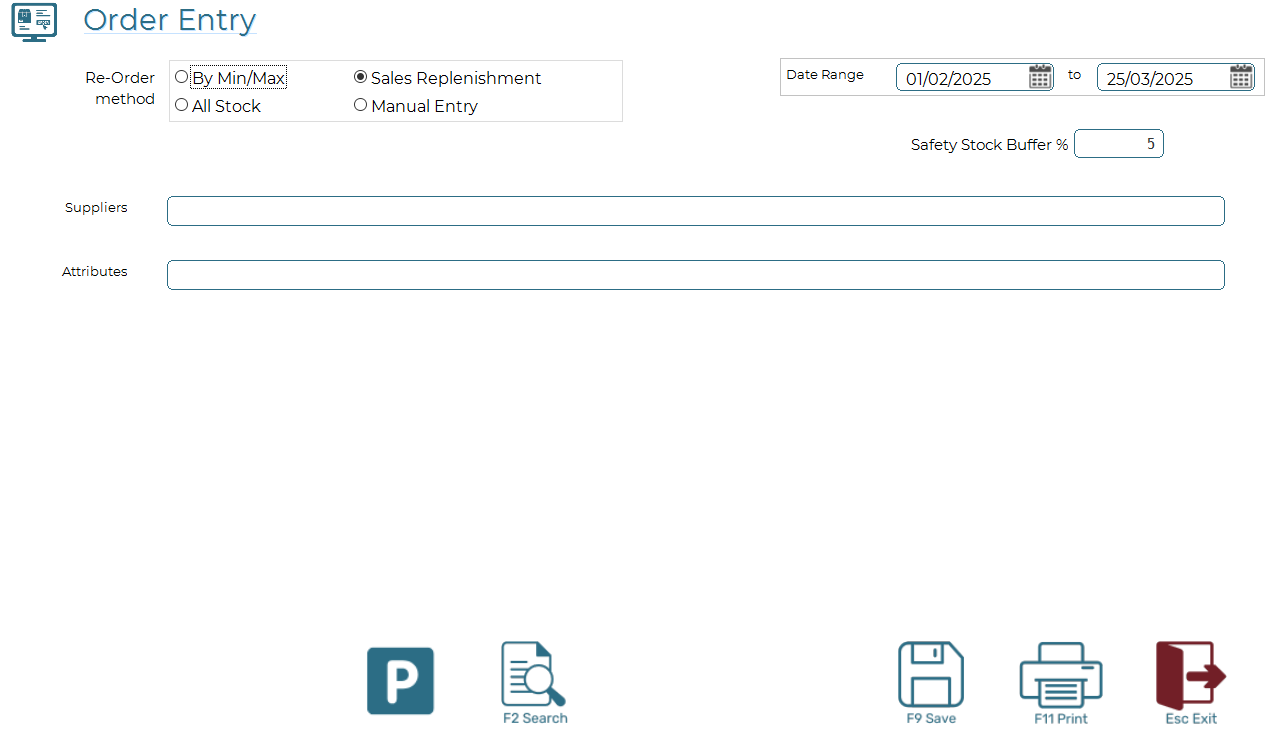

The initial screen allows you to select the type of order processing you wish to use.

By Min/Max

Min-Max ordering ensures optimal stock levels by automatically generating purchase orders when inventory falls below the set minimum quantity. The system replenishes stock up to the defined maximum level, preventing shortages and overstocking. This method helps maintain efficient inventory management with minimal manual intervention.

Sales Replenishment

Sales replenishment ordering generates purchase orders based on recent sales data, ensuring stock levels align with demand. The system analyses sales trends over a defined period and recommends reorder quantities to maintain optimal inventory, preventing stock-outs while avoiding excess stock.

All Stock

The same as Sales Replenishment above except all stock is considered rather than just items that have sold in a set period.

Manual Entry

This method allows you to simply enter the stock items and qty to order with no assistance.

All ordering methods, except the manual option, account for items already on order. For example, if you need six items but have an outstanding order for four, the system will only order two. Additionally, pack quantities and economic order quantities are enforced, which may occasionally lead to temporary overstocking due to supplier minimum order requirements.

Producing Orders

once orders are saved the system